Have you ever encouraged someone to show their mettle, to demonstrate that they were ready for a challenge? Often, showing one’s mettle indicates an ability to endure pressure or exhibit strength. It is no coincidence that mettle and metal are homonyms, as the two words once were used interchangeably. And there are indeed metals whose most well-known properties are strength, such as steel, tungsten, and chromium, as well as alloys like Inconel®.

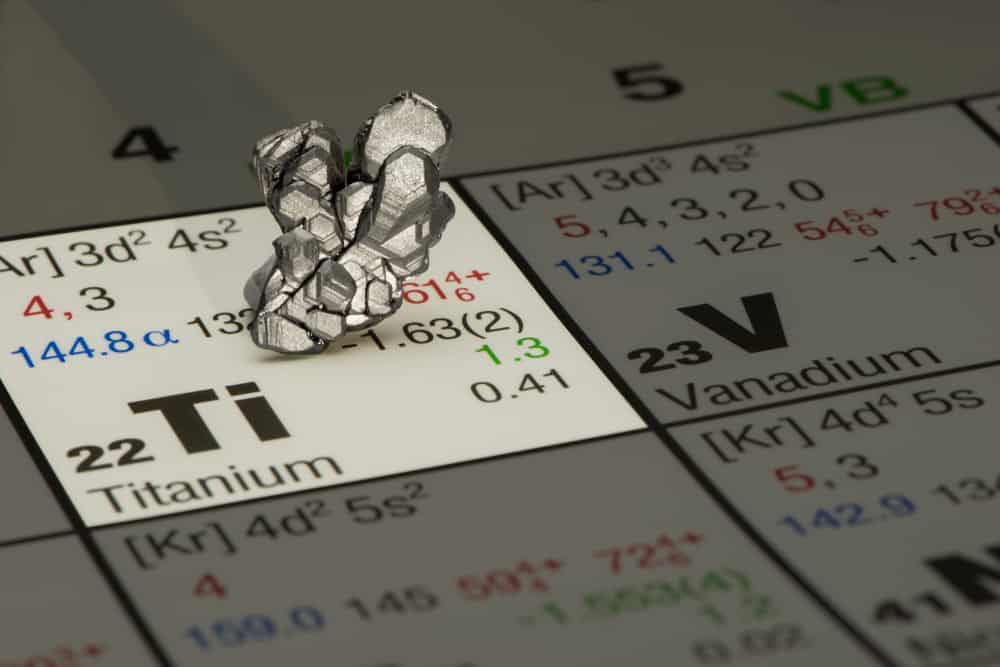

Titanium, another strong metal, not only possesses strength but is also lightweight when compared to steel. Considering titanium’s wide-ranging advantages, it may seem like a super metal to many manufacturers. Yet, titanium’s corrosion resistance may be the property that best illustrates its suitability for many welding applications.

Properties of Titanium

Titanium derives its name from the Titans of Greek mythology, and perhaps this contributes to its status as an extraordinary metal. Of course, titanium’s properties—listed below—provide ample support for its acclaim.

| Properties of Titanium |

| Properties | Value |

| Density | 4.51g/cm3 (0.163lb/in3) |

| Melting point | ≅1668°C (3035°F)* |

| Boiling point | ≅3260°C (5900°F)* |

| Solidus/liquidus | 1725°C (3135°F)* |

| Heat of vaporization | 9.83MJ/kg* |

| Specific heat | 0.5223kJ/kg K* |

| Heat of fusion | 440kJ/kg* |

| Thermal conductivity | 11.4W/m K* |

| Thermal coefficient of electrical resistance | 0.0026/°C* |

| Coefficient of thermal expansion | 8.41µm/m K* |

| Tensile strength | 240MPa (35ksi)* |

| Young’s modulus | 120GPa (17 x 106psi)* |

| Hardness | (70-74)HRB* |

| Poisson’s ratio | 0.361* |

Several properties listed above stand out. For example, the metal’s strength and relatively low density—almost half of steel, depending on the alloy—are the basis for its widespread usage. Today, titanium applications range from paper and paints to biomedical implants and aerospace systems. And titanium has several attributes that make it ideal for welding.

Attributes for Welding

Titanium’s impressive strength-to-weight ratio is beneficial for welding in areas like aerospace and automotive systems as increasing operational efficiency (speed and distance vs. energy usage or fuel cost) is a constant objective. For hot wire welding, materials resistant to current flow can be helpful. Additionally, titanium is resistant to deformation due to increased heat. Titanium is also ductile and maintains its shape well under strain. Finally, a particular titanium property that is not always highlighted but has contributed to its expanded usage is its corrosion resistance.

How to Best Leverage Titanium’s Corrosion Resistance

Perhaps, the titanium corrosion resistance property was not always well-known. Today, though, this attribute is one of the most cited reasons manufacturers opt for titanium instead of other metals. This expanded application usage, which is likely to continue to grow, in many cases depends on following guidelines to align your welding process with titanium’s strengths.

Guidelines for the Best Titanium Welding Utilization

- Leverage titanium’s corrosion resistance property

Resistance to corrosion allows titanium to be used in areas where moisture is likely—and even in aqueous welding environments for applications such as shipbuilding.

- Use tungsten electrodes

When welding titanium, tungsten electrodes can be an ideal selection due to their strength, durability, and variety; however, you should select a type based upon the specific requirements for your application.

- Cleanliness is key

When working with titanium, make sure to keep the weld environment (weld pool and air around it) free from contamination. Failing to do so will cause the metal to degrade and can lead to immediate or premature cracking or breaking.

- Avoid nitrogen and oxygen

Nitrogen and oxygen should be avoided when using titanium, as they can diffuse into it at temperatures above approximately 400°C and cause brittleness and cracking.

- Use argon or helium for shielding gases

Both helium and argon are recommended as shield gases for TIG welding titanium because they promote a clean working area, which is critical to prevent the early failure of welded titanium systems. Adequate gas coverage around the weld zone, surrounding the the arc and on the inside below the arc, is critical when welding titanium.

- For piping systems, use an orbital process

Titanium offers several advantages; however, it does require precision and consistency. For best weld results, employ an orbital welding process rather than a manual one.

- Use a remote pendant or robotics for safety

Although titanium is one of the safest metals in terms of toxicity, welders must still avoid hazards from fumes. These can include problems breathing, chest pains, skin and eye irritation, and pleural disease. The best way to avoid these issues is by implementing an automated process that utilizes programmed welding robots or an orbital welding process with remote pendant control.

Is titanium a super metal? That may be debatable; however, its utilization, due in large part to titanium’s corrosion resistance, is not.

Arc Machines, Inc. has the experience, expertise and equipment to perform cold and hot wire, fusion, and cladding welding operations to the highest quality. Our expertise covers applications that seek to optimize titanium’s corrosion resistance and other superior properties. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.