Most industries today are subjected to high standards for productivity and quality. And they are addressing this challenge by embracing robots and their automated advantages. The growing interest can be seen in the latest numbers, which valued the sales of robots at $2.38 billion in 2022.

The welding industry is no exception in this race. Robotic welding, with its automation and programmability features, has attracted the keen interest of manufacturers to perform welding tasks in a wide range of industries, including aerospace and automotive. Most notably, in critical applications like the tube to tube sheet welding, a process that is highly precision-oriented, time-consuming, and labor-intensive, the use of robotic welding arms has automated the process to meet the relevant industry standards for quality and consistency.

The Main Concerns of Tube to Tube Sheet Welding

Before we discuss the need for a robotic welding arm, let us take a look at tube to tube sheet welding and the challenges of performing such a welding process.

| Tube to tube sheet welding is simply the process of creating a strong and leak-free joint between tubes and a tube sheet. The tube sheet is a flat metal sheet with holes to allow tubes to pass through. |

Such welding is prevalent in applications that include the use of heat exchangers, pressure vessels, or steam generators where joint quality requires ultimate strength and leak-tightness. The precision in tube to tube sheet welding is necessary to address:

| Extreme operating conditions | Temperature ranging from 600-1000°C. Pressure conditions that span from 15 to 1000 psig. |

| Tubes and their spacing | A large number of tubes (count going up to hundreds) attached to tube sheets.Close proximity of the tubes—the recommended spacing is 1.5 to 2 times the outer diameter of the tube, with minimum spacing being 1/4 inch (6mm). |

| Material compatibility | The use of compatible filler metal and shielding gas.Prevention of issues like corrosion, cracking, distortion, or other forms of material degradation. |

| Quality control | Meeting industry standards and quality requirements for welding parameters, material selection, heat treatment requirements, etc. |

Manual welding is impractical in addressing these precision requirements because of the inability of the welder to access each joint and perform the weld safely and consistently.

The task of implementing the ideal welding process in a safe and efficient manner is better handled by the “arms” of robotic welding.

Robotic Welding Arm: Tube to Tube Sheet Welding Advantages

An effective tube to tube sheet welding involves properly handling and aligning tubes and welding each of them to the tube sheet with a high degree of precision to produce a strong joint. The robotic welding arm offers this precision and consistency with its automated approach. The arm can be set up and programmed easily to hold the tube in place and perform welding as per the set parameters. The welding process can be constantly monitored to ensure uniformity of every single tube to tube sheet joint.

There are several other advantages of using a robotic welding arm, which are:

- Flexibility: Whether the tube to tube sheet joint is protruding, recessed, or flush, the robotic welding arms can flexibly access all joints and perform welding in any position.

- Quality and Consistency: The robotic welding arms can be programmed to maintain consistent weld parameters throughout the process. This ensures high precision and accuracy, leading to high-quality welds that meet industry standards.

- Productivity: The ability of robotic welding arms to operate continuously, even for complex welds in constricted space, makes it possible to achieve a higher yield compared to the manual option.

- Waste Reduction: Using a robotic welding arm ensures the joint is of high quality and doesn’t need rework. It also controls the amount of filler metal used, ensuring only the optimal amount goes into the process.

- Safety: When working in a hazardous environment or with hazardous metals or fumes, using a robotic welding arm is beneficial for ensuring worker safety.

- Cost-efficiency: With reduced waste, continuous operation, weld consistency and quality, and reduced need for manual labor, the robotic welding arm proves to be the most cost-efficient option.

Robotic Welding Solution For Simplifying Tube to Tube Sheet Welding

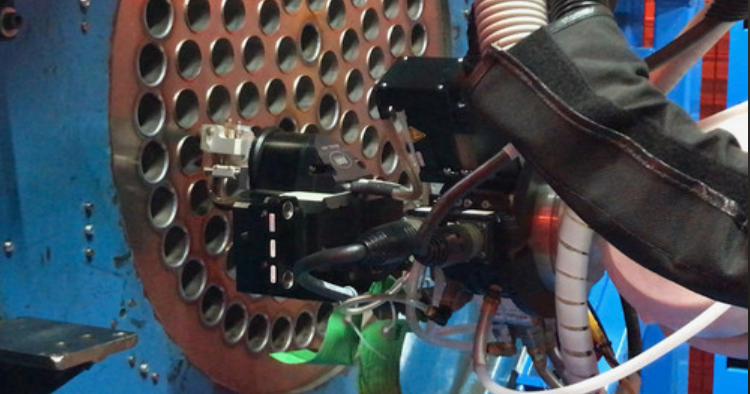

For manufacturers seeking complete automation in welding, robotic welding arms are a crucial part of the integrated system. These systems are usually equipped with a welding head at the end of the robotic welding arm, which is programmed to move in a controlled path and provide heat input with high precision and accuracy. These welding arms, together with other monitoring and control systems, can perform highly complex welds, such as tube to tube sheet welding, with far more ease and efficiency.

AMI’s Model M60 / M60R / M23 is an automation-ready tube to tube sheet weld head. The integrated weld head and the robotic system show compatibility with AMI or other third-party automated welding solutions to create a complete automated welding process. With a fully automated and programmable system, the integrated robotic welding system (robotic welding arms, weld heads, control system, and monitoring system) can produce an effective solution to complex tube to tube sheet welding problems.

Arc Machines, Inc. has been a leading provider of a wide range of orbital welding solutions specializing in tube to tube sheet welding for decades. The robotic welding systems such as the AMI’s Model M60 / M60R / M23 are integrated systems of robotic welding arms with weld heads and control and monitoring systems that are automation-ready for your complex welding applications. For inquiries regarding how this product can help you achieve the desired productivity and quality, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines Inc. welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.