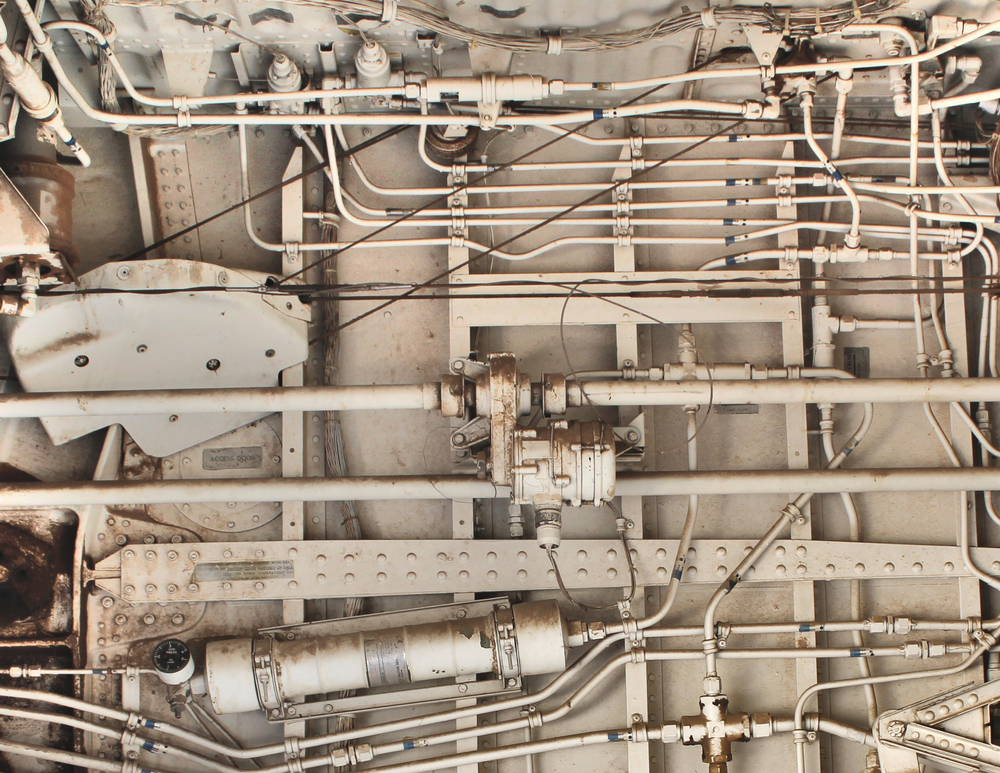

All aircraft, small and large, require a flow system to transport the fluid to different systems that require it. This is done by fluid lines, which are used in transporting combustion fuel, oil, hydraulic fluids, oxygen, coolant, and other fluids critical to the proper functioning of the aircraft. This makes the fabrication choice of fluid lines and fittings in the aviation industry an essential part of the production process.

The fluid lines are designed with rigid metallic tubing or a flexible hose. During the installation of rigid fluid lines, it is essential to consider the possibility of leaks and damages due to factors like vibration, pressure, and temperatures. Therefore, orbital welding these lines is the wise option as it provides controlled fusion to form clean and robust welds.

Fluid Lines And Fittings in Aviation Industry

Normally located in the aircraft wings, the fluid lines are metal tubes that are connected by fittings to ensure a smooth fluid transfer. The rigid lines are preferred for stationary applications where the tubes may be laid out in a relatively straight line. For optimal performance, these fluid lines and fittings are required to have:

- High strength

- Airtight seal and leak-free build

- Corrosion-resistant and lightweight material

- High temperature and pressure resistant

The most important thing to note in the installation of fluid lines is the atmospheric pressure. Aircraft may experience constant fluctuation in atmospheric pressure due to changes in altitude or weather. This can be enough to cause the failure of the fluid lines and fittings that are not installed to perfection.

The attempt at perfection starts from the material selection for the fluid line and extends to selecting the ideal welding method for their installation. The rigid fluid lines are generally made of aluminum, carbon steel, stainless steel, or titanium.

Aluminum can be used for low or medium-pressure applications or in vacuum lines. Thin-walled steel tubings can be used to fulfill high-pressure requirements such as for landing gears. Titanium tubes are strong and lightweight, making them a perfect choice for a “high-performance” airplane. However, it is to be noted that titanium must not be used with oxygen, as its high reactivity to the gas will lead to loss of strength and other mechanical characteristics.

Once the material selection is made, implementing processes like orbital welding is critical in ensuring strong and reliable welding of these fluid lines.

Orbital Welding For A Safe Fluid Lines And Fittings Aviation Installation

Welding in the aviation industry requires adherence to high industrial standards to ensure flight safety. The fluid lines also need to meet all the basic preparation and design requirements for tube welding. Here are some requirements that should be met:

- The tubing material should be compatible with process fluid

- The tube thickness must be calculated to provide enough strength to withstand the operating pressure and the occasional fluctuation

- The tube size should be a proper fit, i.e., ensure optimal volume and velocity, even in fluctuating demands

Orbital welding can meet these demands with its controlled and precise welding ability. The automated system of orbital welding offers the calculated movement of the weld head, which can be controlled remotely. This is very beneficial for welding in cramped spaces, which often is the case with fluid lines where assembly and repairs have to be addressed in confined spaces like the wing’s interior.

Additionally, when welding with TIG, orbital welding equipment offers controlled heat input and gas flow to ensure the formation of strong, pure welds that are free of contamination and defects. The result: high-quality fluid lines that are leak-free can be assembled and address all fluctuating pressure and temperature that the aircraft demands.

Welding Reliability For Aviation Production

The increasing complexity of aircraft design demands more safety in the aerospace industry. Fluid lines and fittings, which control the entire functioning of the aircraft, must be welded and installed with the highest standards. The provision of ideal tube material, orbital technology, TIG welding, and weld electrodes will provide the uniformity and reliability that is required for creating a quality weld.

You can always trust AMI to deliver the right solution for your aviation welding needs.

Arc Machines, Inc has been a leading producer of high-quality orbital welding equipment since 1976, with its advanced welding machines and selection of electrodes that are compatible with welding fluid lines and fittings in the aviation industry. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.