The science of metallurgy focuses on the chemical, physical, and mechanical composition of a metal and its alloys. And it carries special importance for welders because a metal’s attributes may be altered during the fusion process thermal cycles. Basic knowledge of welding metallurgy is, consequently, a great benefit for welders.

Basic Terminology of Welding Metallurgy

Welding metallurgy focuses on the interactions occurring during the welding processes that directly influence material properties. When a material is welded using a typical arc welding process such as GTAW (Gas Tungsten Arc Welding), phase transformation and microstructure evolution result in changes to the alloy’s attributes from the rapid heating and cooling. The reaction time is comparatively short, as compared to reaction times during forging, casting, or heat treatment. By understanding these physical, chemical, and mechanical characteristics, welders can discover opportunities for improvement. The basic metallurgical parameters that affect weldability are discussed below:

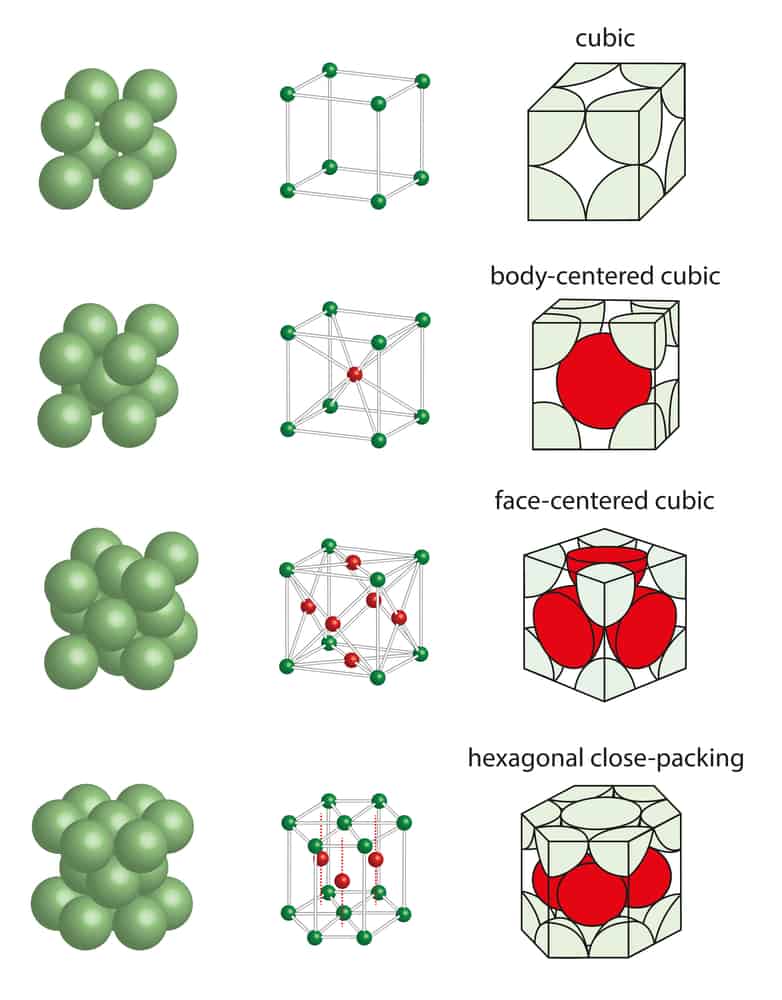

Crystal Structure

Crystal structure refers to the arrangement of molecules or atoms of the metal. In a molten state, the metal does not have a fixed structure and can move freely with the aid of heat input. As solidification occurs during cooling, 3D patterns that can include face-centered cubic (FCC), body-centered cubic (BCC), and hexagonal close-packed (HCP) structures form. These structures are susceptible to change at different temperatures.

Phase transformation

At a certain temperature, the crystal arrangement of the metal changes. This change is referred to as phase transformation. For instance, iron can change from a BCC structure at 910℃ to an FCC structure at 1388℃. The transformation can be observed at different states—like when the crystal structure dismantles during liquefaction under heat input and reestablishes when solidification occurs. The structure can be defined with the help of the phase diagram, which predicts the phases based on alloy composition and temperature. At equilibrium, the metal is considered to be stable. However, due to rapid temperature changes during welding, equilibrium is difficult to attain.

Microstructures

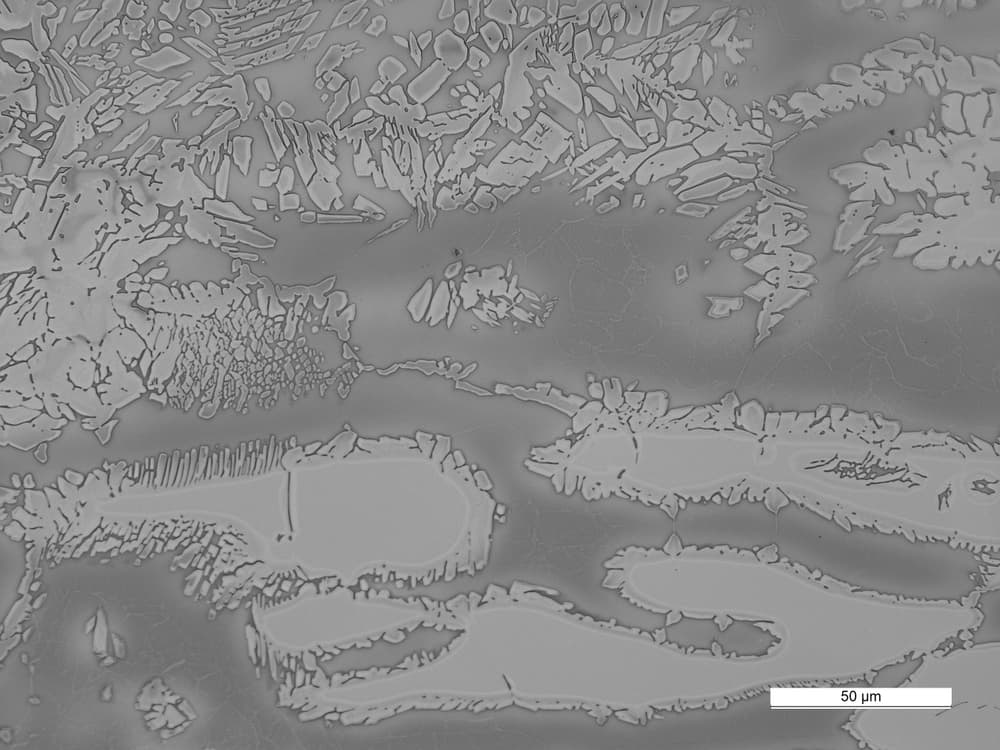

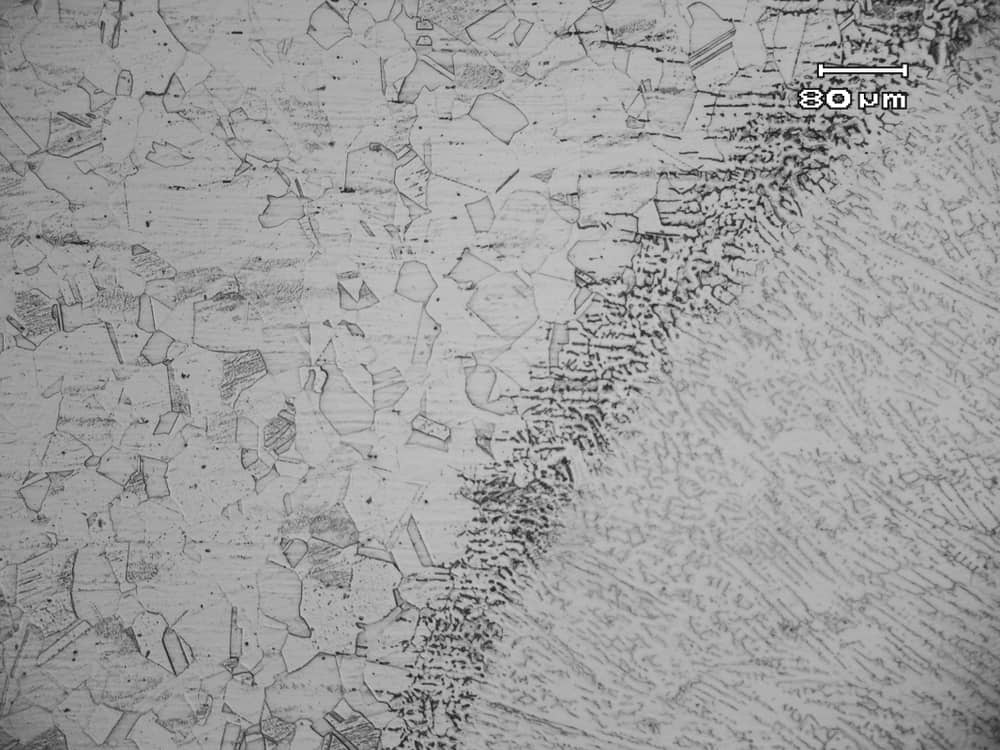

The weldability of the material depends on its microstructure. Microstructure indicates the grains, grain boundaries, and phases that collectively define the arrangement and attributes of the alloy. It is, however, affected by the chemical composition and the thermal cycles to which the weld joint is subjected.

For instance, during the welding of steel, a filler metal with different composition is generally used. In instances where the same metal is used, brittle martensitic microstructure formations are more likely. This is further exacerbated by the rapid cooling of the weld pool. Similarly, when heating the weld pool close to the fusion boundary, austenite is formed, which on rapid cooling forms a microstructure different from that of the parent material. The complexity of the microstructure formation can be examined further on the regions of fusion weld.

Heat Affected Zone

The area in the base and weld metal where all the welding interaction occurs and phase changes occur is the heat-affected zone (HAZ). This is the region where the microstructure and mechanical attributes have been affected by heat input during the weld. The microstructure of the HAZ is determined by the extent of temperature distribution during the thermal cycle. The unaffected base material can be found further from the HAZ.

The width of the HAZ itself is also affected by the heat input and the welding process, with each weld pass forming its own HAZ.

Orbital Welding for Optimal Metallurgical Formation

The concept of welding metallurgy is vast and considerable explanation is necessary to understand the relationships among material composition, chemical reaction, heating and cooling, and weld defects that influence the final weld result. Although introductory, the above introduction captures the importance of welding process selection and parameter control needed to achieve welds with optimal properties.

Arc welding processes such as GTAW offer an attractive option due to their enhanced speed and control benefits. Additional benefits emerge through automated technology such as orbital welding, enabling welders to run a controlled thermal cycle and eliminate defects common to manual welding.

Arc Machines, Inc. specializes in high-quality, precision orbital welding that supports your industrial welding problem. A basic welding metallurgy knowledge combined with our solutions can ensure that your high-quality industrial systems are resilient to weld defects throughout their service life. For inquiries regarding products, contact sales@arcmachines.com. For service inquiries, contact service@arcmachines.com. Arc Machines welcomes the opportunity to discuss your specific needs. Contact us to arrange a meeting.