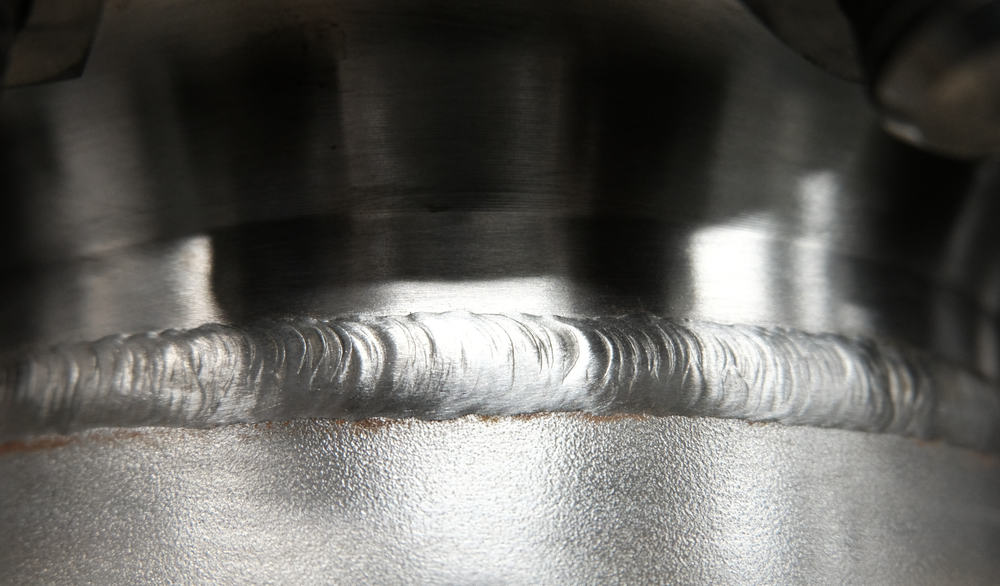

Stainless steel has transformed industries since its invention in the 1900s. Excellent mechanical properties, corrosion resistance, and cleanliness have contributed to its versatility and enabled the metal to be used in manufacturing products as diverse as surgical equipment and spacecraft. Because stainless steel is a popular material across wide-ranging manufacturing environments, it must adhere to many fabrication and manufacturing standards. As such, welding stainless steel also requires thorough consideration.

Various grades of stainless steel require different parameters during welding and a variety of welding process implementations. When performed with orbital welding, operators can more easily overcome the many challenges of stainless steel welding and obtain high-quality results. This article will explore the parameters, welding types, and challenges of stainless steel welding.