In any pipe welding project, operators must consider many factors to ensure that the pipe welds can withstand extreme temperatures, pressures, loads, stresses, and other external forces to comply with industry-specific standards. Pipe welding specifications such as arc voltage control, amperage, travel speed, the addition of filler material, and electrode oscillation vary across industries.

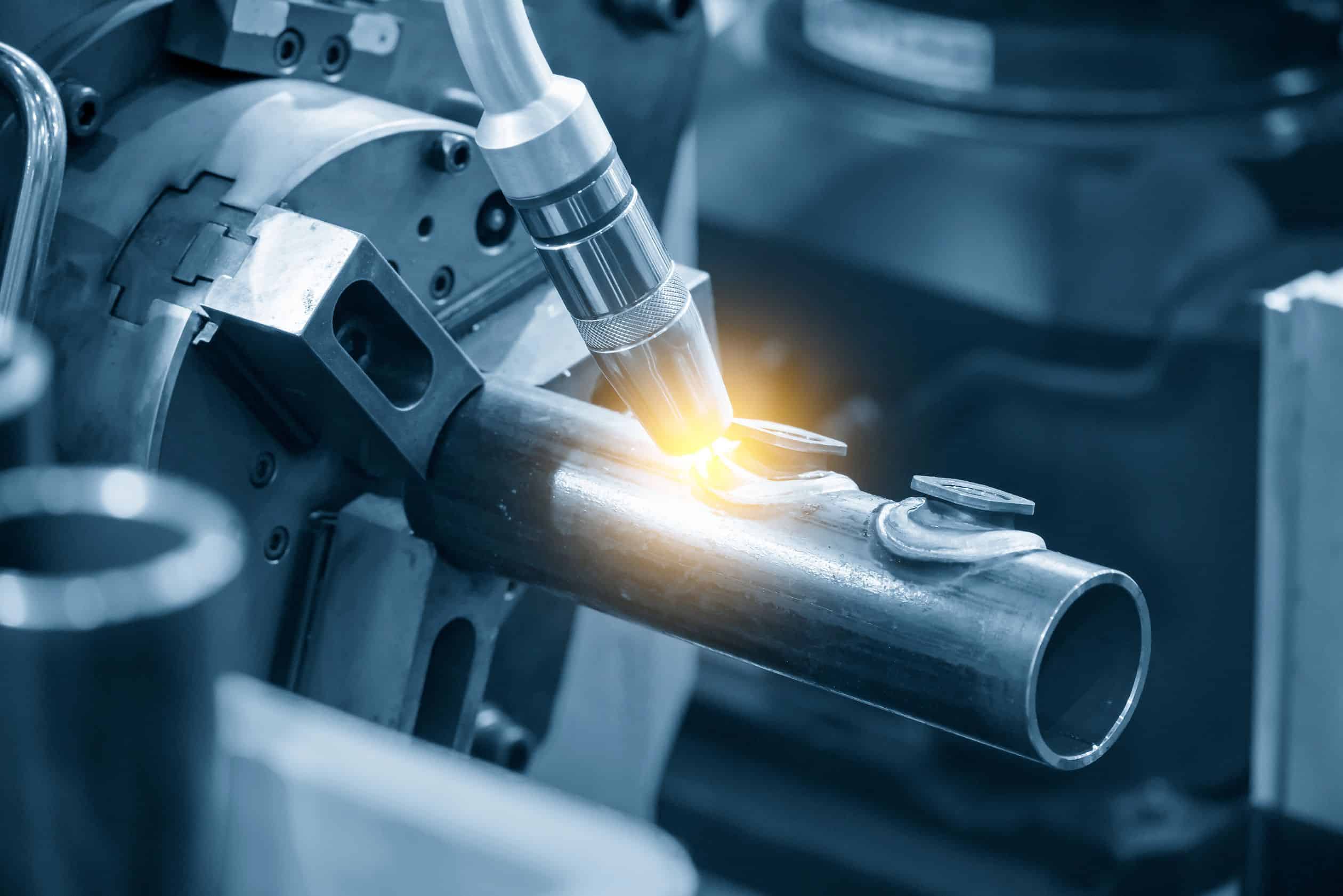

Pipe welding automation such as orbital welding makes it easy to adhere to these specifications during the welding process with speed, consistency, and accuracy that are difficult to achieve through manual welding.

Below, we discuss how pipe welding automation helps address various industry-specific challenges in the welding process and why orbital welding is particularly well-suited for welding pipe and tube in high-precision and high-stress applications across industries.