In industrial settings, components including pipes in refineries and factories or tubes in heat exchangers and industrial condensers are often aligned in a very close sequence. The integrity and strength of these components play a crucial role in operational performance. So, any construction and repair work needs to be highly specified and based on industrial standards. However, given the confined configuration of these components, welding for these applications can be difficult.

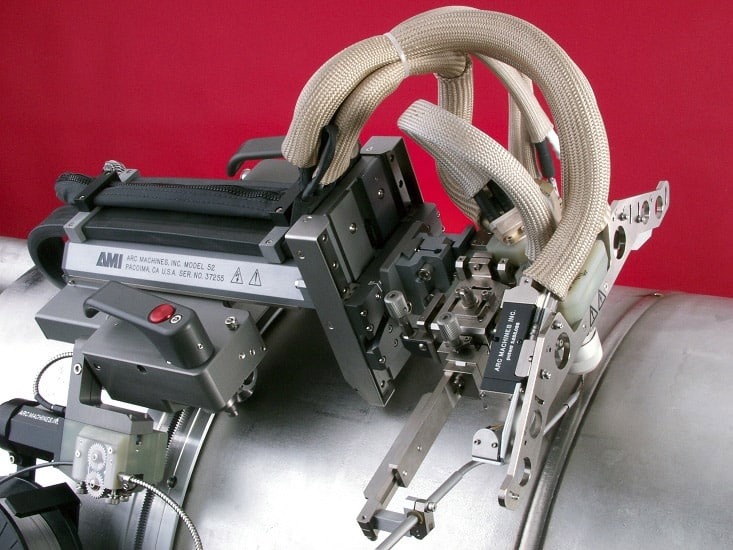

Ensuring ideal high specification welding operation in such spaces requires a technology that can operate and produce high-quality, low-clearance welds. Optimal outcomes can be difficult to achieve with manual welding. Low orbital weld head clearance capabilities, however, enable welders to perform consistent and reliable welds in confined areas while ensuring maximum welding safety.