Accuracy, efficiency, and productivity are the key results industries seek when selecting technologies for their welding application. Equipment, including different types of TIG (Tungsten Inert Gas) weld heads and power supply systems, can facilitate programming and optimizing weld parameters to ensure precise welds. An automated orbital TIG welding process enables industries to achieve the most reliable and highest quality outcomes. Arc Machines Inc. (AMI) helps deliver excellence and meet industry standards in welding with its durable and reliable range of orbital TIG welding equipment.

AMI Weld Head and Power Supplies: Specialized Orbital TIG Welding Equipment

Orbital TIG has been a primary choice for pipe and tube welding applications across industries. This process has enabled manufacturers to achieve the best weld results by combining the automation and control of an orbital system with the clean and high-quality TIG welding process. Additionally, with specialized equipment—such as orbital weld heads and power supplies—manufacturers can extend the benefits of their welding process for optimal speed, consistency, and precision.

Orbital TIG Weld Heads

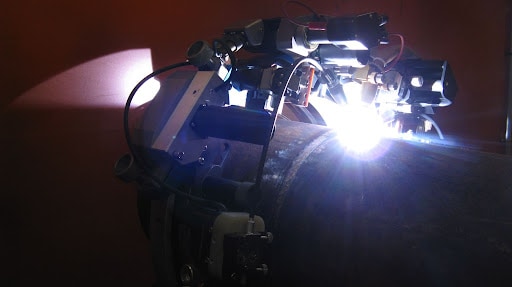

Weld heads are orbital welding components, as they facilitate fusion for various pipe diameters, material thicknesses, and material types. The orbital weld head makes this possible by holding the electrode in place while mounted on a guide track attached to the fixed pipe or tube. Manufacturers can select closed or open weld heads for specific weld condition requirements. Closed weld heads are compact and used when sanitary conditions are required, while open weld heads facilitate welding where operating space is limited.

For high-quality results, AMI offers the following weld heads that are compatible with your orbital TIG welding applications:

Power Supplies

Power supplies control the orbital TIG welding parameters in a weld cycle and document the results. Modern programmability functions enable operators to optimize current flow, gas flow, feed speed, and more. This control allows industries to attain their best welds that display excellent consistency, purity, and precision. When making a power supply selection, examine its versatility and compatibility with different welding processes and weld heads.

AMI provides the following list of power sources for orbital TIG welding applications:

Ideal Weld Results With AMI’s Orbital TIG Welding Equipment

Orbital TIG welding requires manufacturers to consider conditions, such as surface preparation, material selection, temperature, and voltage accuracy. The right equipment can help manufacturers ensure accuracy and precision when addressing these conditions. AMI’s orbital TIG welding equipment supports weld efficiency with a mechanized process and weld parameter control and optimization. This enables industries to achieve:

- Repeatable and precise welds.

- Compatibility with a wide range of materials.

- High-purity in welding with excellent shielding.

- Consistent welds across complex geometry.

- Safe welding operation.

Manufacturers can rely on the high-quality output and functionality provided by AMI’s orbital TIG welding equipment to meet their productivity goals.

READY TO CONNECT?

Arc Machines, Inc. is a leading provider of orbital TIG welding equipment that enables manufacturers to boost productivity and ensure welding process safety. For inquiries regarding products, contact sales@arcmachines.com. Contact us to arrange a meeting.