Undeniably, our technologic age exceeds anything that has gone before. The Internet, the Internet of Things (IoT), the Industrial Internet of Things (IIoT), and other revolutionary advances have placed ever-expanding demands on critical industries like energy production facilities. This demand can only be satisfied by secure infrastructures primarily composed of steel pressure vessels, pipes, and tubes.

Narrow gap welding is often required to secure these assemblies because narrow gap, or narrow groove, welding helps ensure strong joints for thick-walled pipes while reducing the necessary material. While narrow gap welding creates opportunities for cost-effective construction, there are challenges that must be overcome. Often, the solutions to these challenges can be found in the welding process and the equipment used.

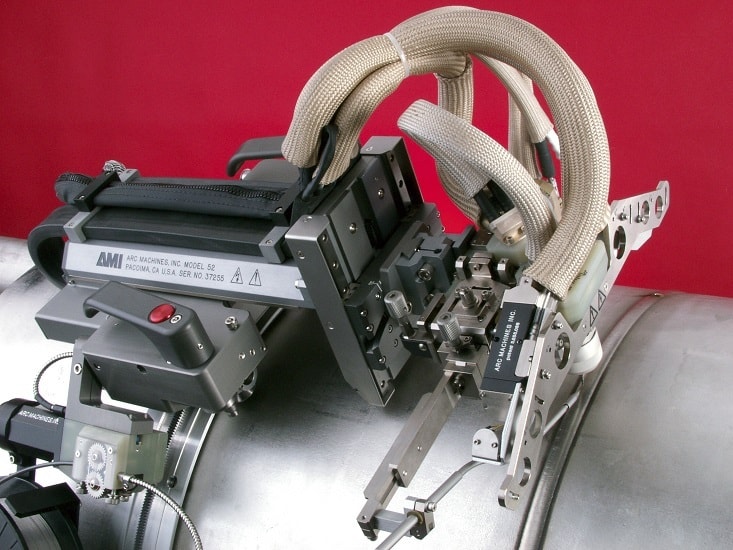

Arc Machines, Inc. (AMI), an industry leader in advanced welding technology and equipment for nearly half a century, has extensive experience supporting the utility industry and other critical industrial operations. The requirements for these applications necessitates that the best narrow groove TIG welding equipment—machines and materials—be utilized. And AMI delivers.