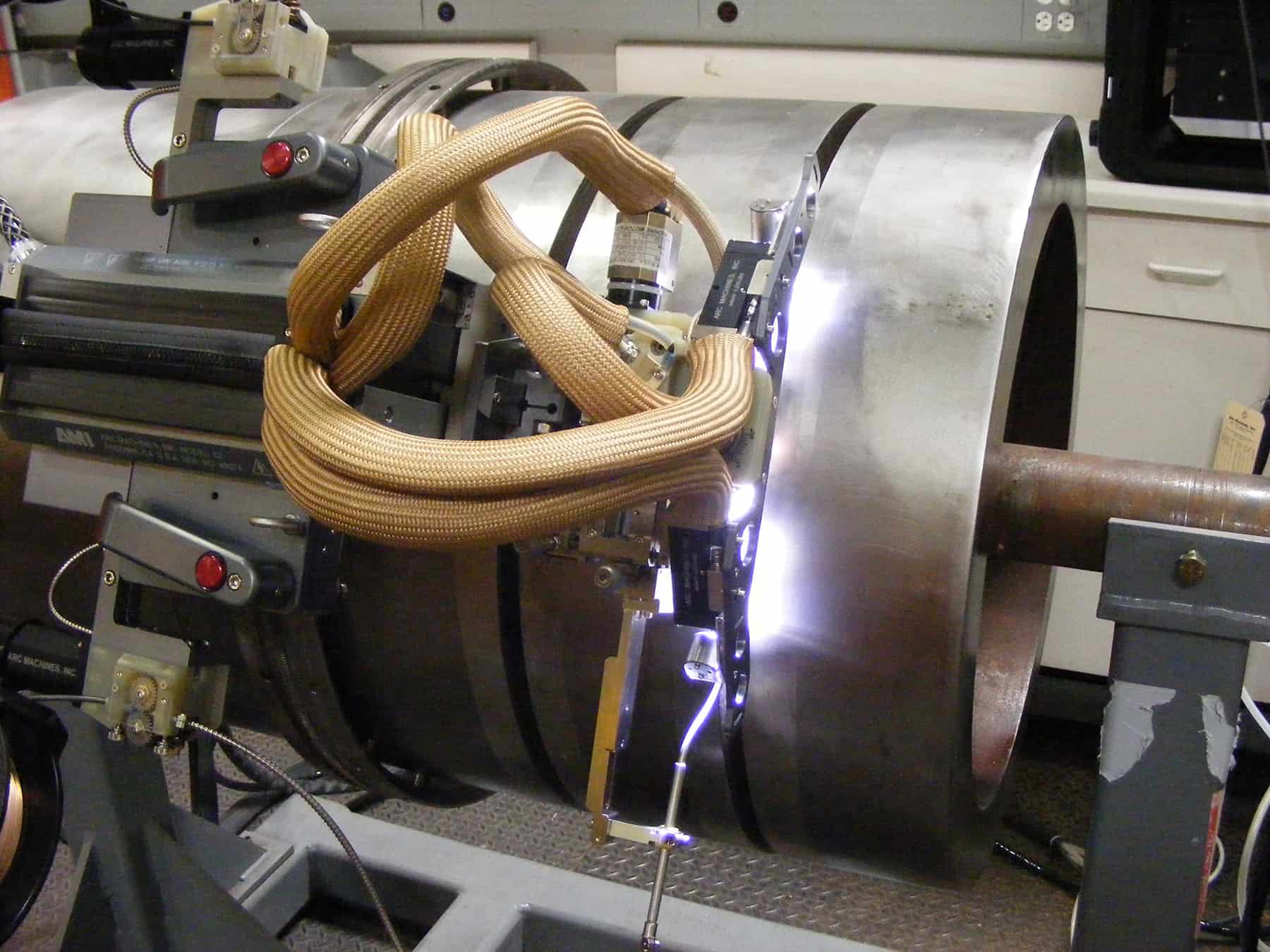

It is generally accepted that TIG welding, or GTAW, produces higher quality welds. And weld consistency, which contributes to weld strength, is often cited as an indicator of TIG welding quality. TIG welding not only produces high-quality welds, though, it is also a versatile process applied across a wide range of applications that include sanitary tube and pressure vessel welding.

GTAW does have its disadvantages, though. In addition to being the most difficult process to master, GTAW can be slow and meticulous when compared to GMAW or MIG welding. However, for some projects, particularly high-spec applications, the cost savings generated by high-quality GTAW can mitigate most other concerns. This is especially true when the welder chooses hot wire GTAW and optimizes the deposition rate. Let’s explore this important quality parameter for TIG welding.